Master Drilling North America’s services are driven by cutting-edge R&D, setting new standards in mining efficiency, safety and innovation. Our advanced solutions optimize resource extraction worldwide.

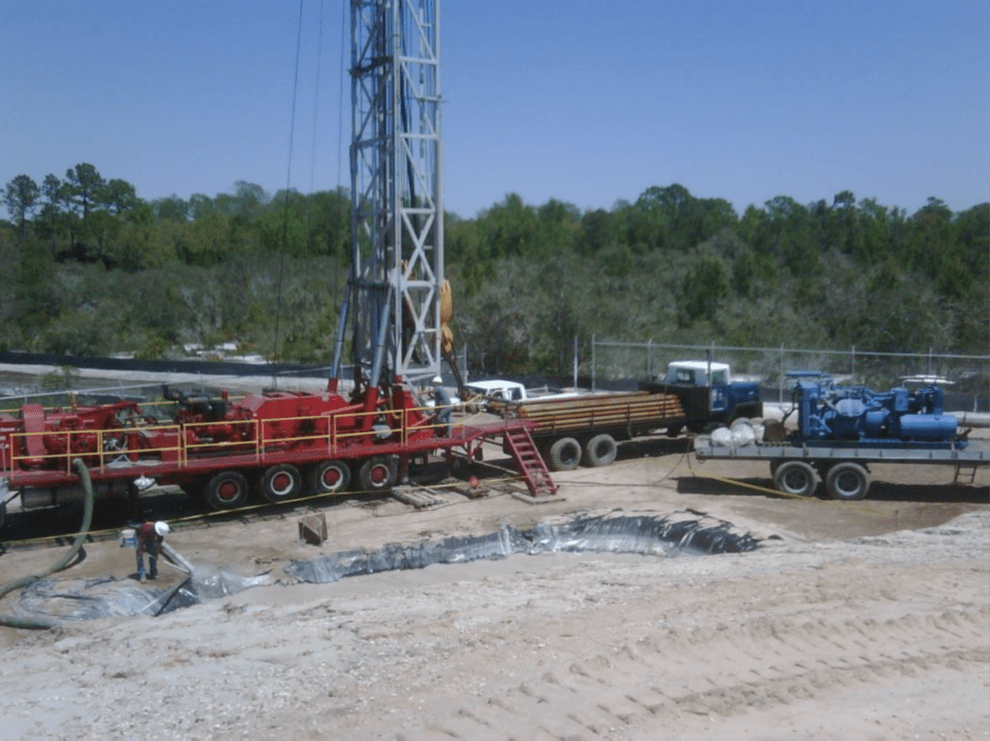

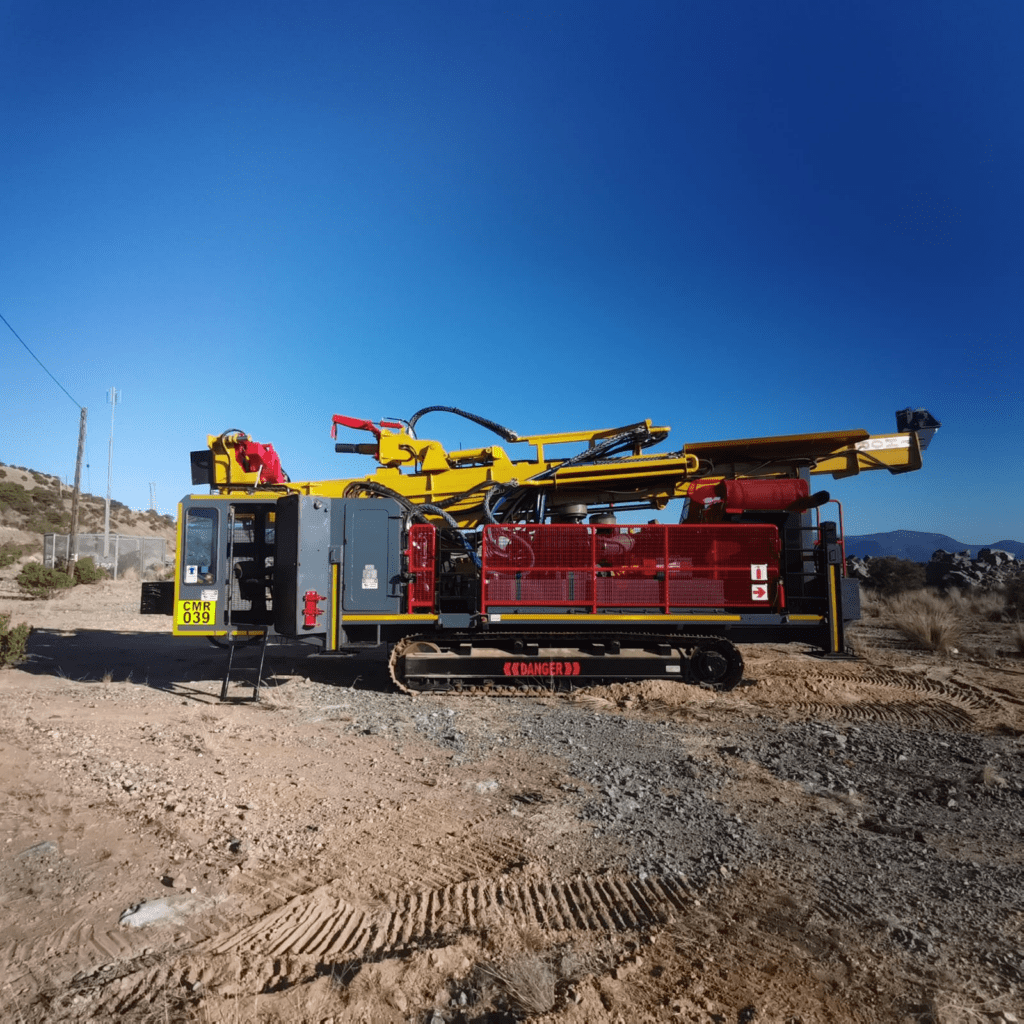

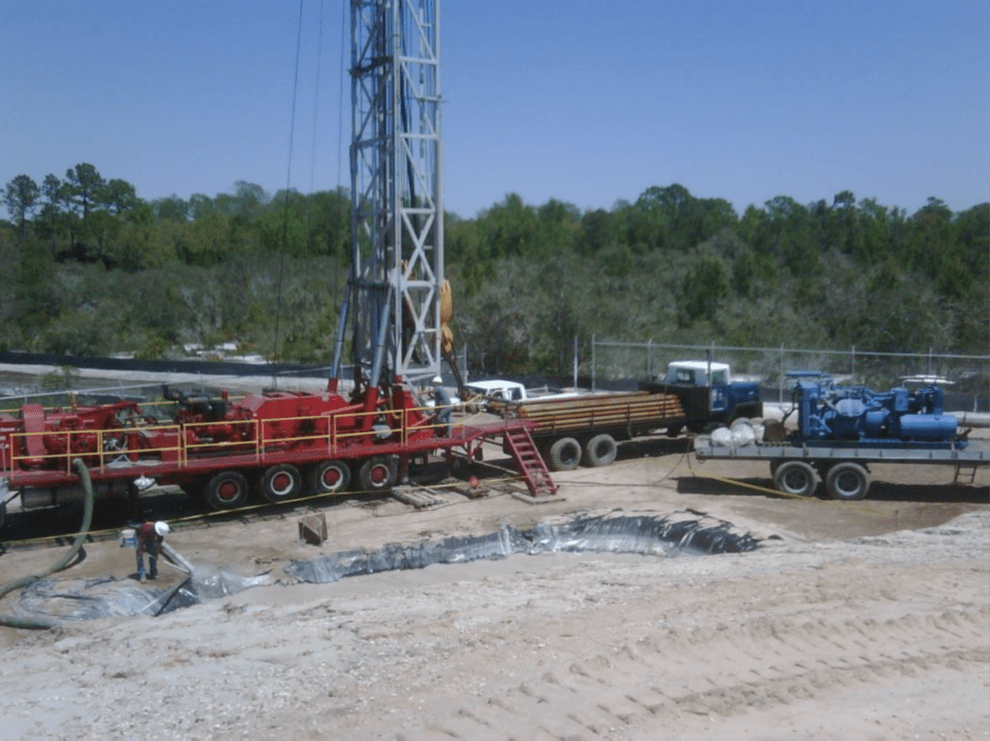

Master Drilling North America provides an extensive range of specialized drilling services, tailored to meet the unique needs of the mining industry across the United States and Canada. Leveraging cutting-edge technology and years of industry expertize, our services are designed to optimize productivity, enhance safety and deliver outstanding results in even the most challenging environments. Whether it’s underground, surface, or remote mining projects, we have the capabilities and solutions to ensure project success.

We are committed to helping our clients achieve their goals efficiently and cost-effectively. By continuously innovating and adapting to evolving industry standards, we remain at the forefront of drilling solutions in North America.

Our rock boring services are designed to cut through the toughest rock formations, ensuring that mining operations can continue without delay. Our equipment is built for reliability and efficiency.

We utilize high-durability tools to withstand extreme conditions, ensuring consistent performance throughout the project.

Our specialized techniques enhance accuracy, reducing material waste and improving project outcomes.

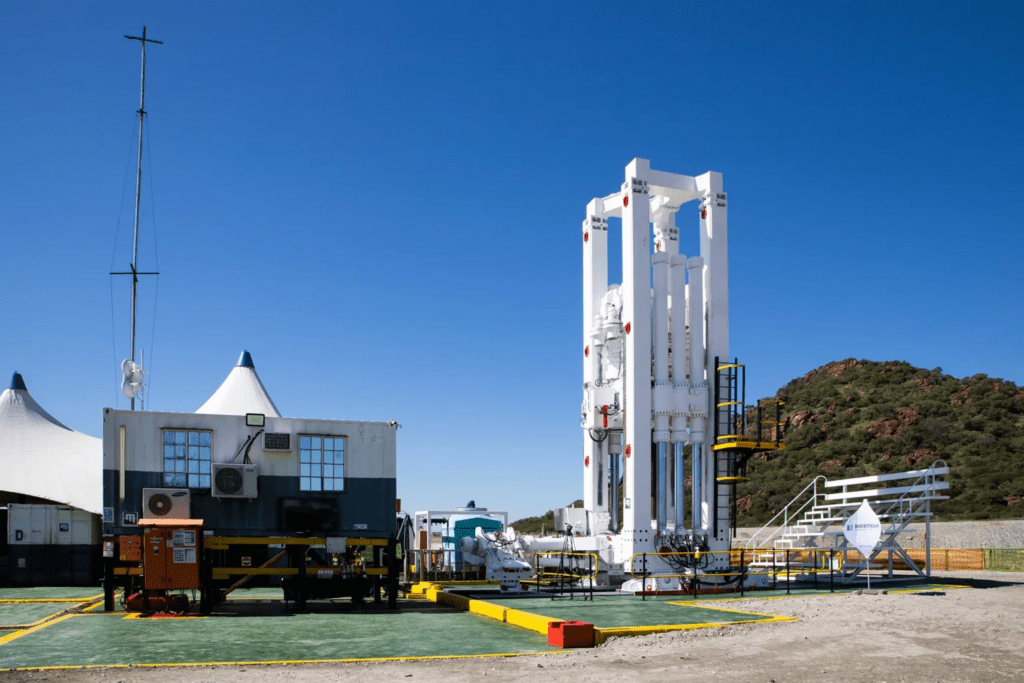

Raise boring is an efficient method for creating vertical or inclined shafts used for ventilation, material transport, or access in underground mines. Our expertize ensures minimal disruption and maximum efficiency.

We deliver precise shaft drilling to meet the specific needs of mining projects, reducing risks and maximizing safety.

Our raise boring solutions improve underground ventilation, optimizing air quality for miners’ safety and health.

An effective technique for deep exploration and geological assessments, allowing efficient material recovery in water-filled conditions.

Enables drilling in challenging, water-logged environments without compromising core recovery.

Ensures high-quality sample retrieval for accurate geological analysis.

Learn more about how Master Drilling North America can help your company grow.

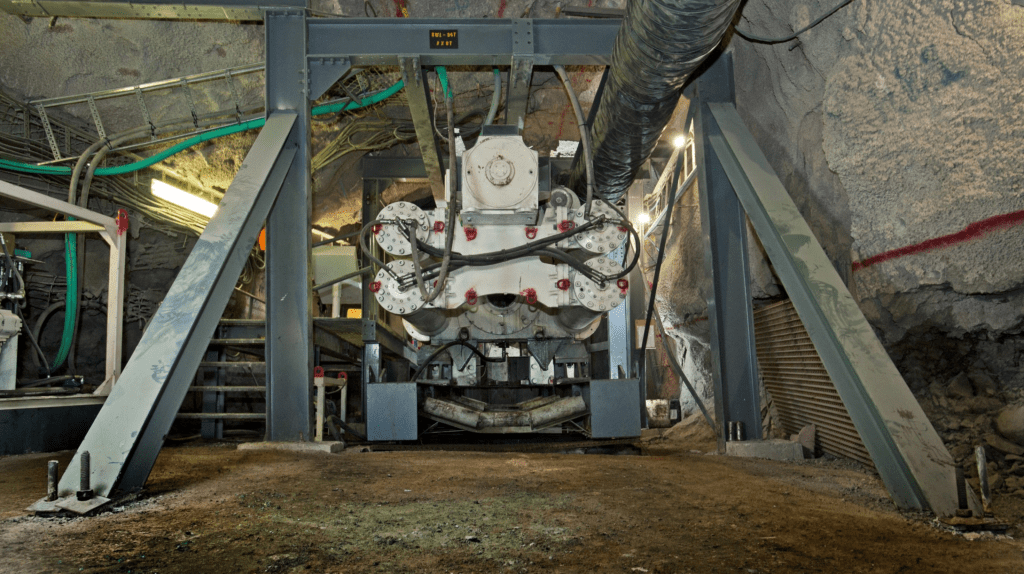

Horizontal boring is ideal for developing tunnels and underground access ways with minimal surface disruption. We provide reliable and accurate horizontal boring to accelerate project timelines.

Our team specializes in creating efficient tunnels, tailored to the unique needs of each mining site.

We focus on delivering cost-effective tunnelling services that do not compromise on quality.

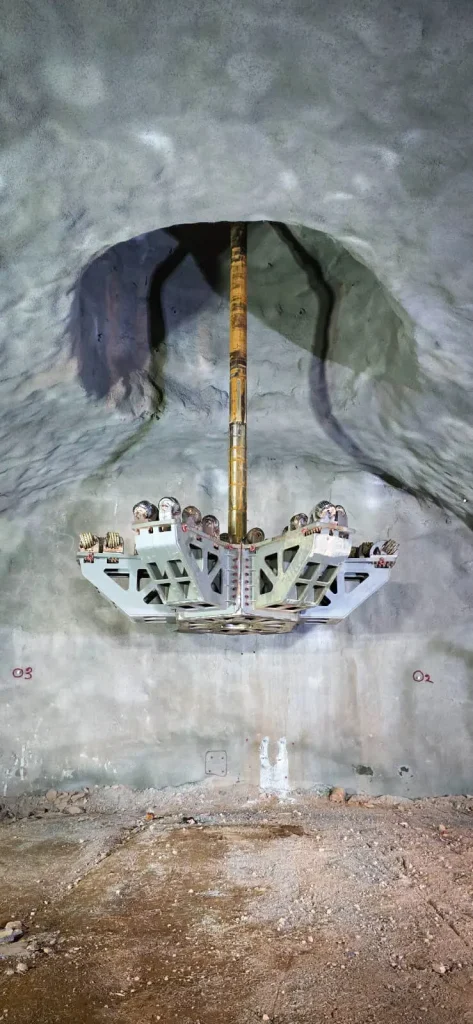

Box hole boring is perfect for developing slot raises and ore passes, enhancing the efficiency of underground mining. We deliver reliable box hole boring solutions to optimize production.

We design ore passes that streamline the flow of mined materials, boosting operational efficiency.

Our techniques ensure fast and precise slot raises, reducing project timelines.

Our slot boring services are designed to maximize ore extraction while minimizing waste. We use advanced methods to ensure the most efficient resource utilization.

We focus on selective ore extraction, minimizing waste and maximizing the yield of valuable minerals.

Our environmentally conscious techniques reduce the impact on surrounding areas, promoting sustainable mining practices.

A precise method used to extract cylindrical rock samples for geological analysis and resource evaluation. This method allows geologists to obtain undisturbed samples, ensuring detailed stratigraphic assessments and mineral identification for resource classification and feasibility studies.

Provides high-quality core samples for detailed mineralogical studies. The extracted cores maintain structural integrity, offering reliable data on rock formations, mineral composition and deposit continuity, essential for mine planning and development.

Helps determine ore body structure and grade distribution. Through precise sampling and geochemical analysis, core drilling enables mining companies to accurately model ore deposits, optimising resource extraction and financial forecasting.

A rapid drilling technique that uses repeated impacts to break rock formations. This method is highly effective in hard rock conditions, providing efficient penetration rates while maintaining structural integrity, making it ideal for preliminary exploration, overburden removal and foundational drilling in mining operations.

Ideal for initial exploration and overburden removal. This method is particularly useful for breaking through tough rock formations quickly, allowing for deeper penetration in less time, making it an excellent choice for cost-effective, large-scale drilling projects.

Provides quick geological assessments for early-stage projects. With rapid drilling capabilities, percussion drilling minimises delays and reduces operational expenses, ensuring that mining companies obtain accurate subsurface data while maintaining budget efficiency.

A method that uses drilling fluid to cool the drill bit and stabilise boreholes. This technique enhances drilling efficiency by reducing friction, preventing overheating and maintaining borehole integrity, making it highly effective for drilling in unstable or unconsolidated formations where structural support is crucial.

Effective in unconsolidated ground conditions where air drilling is unsuitable. This method allows for continuous drilling without destabilising the surrounding soil, making it ideal for geotechnical investigations, groundwater monitoring and resource exploration in areas with loose or shifting formations.

Maintains hole integrity in challenging environments. By using drilling fluids to stabilise the walls, this technique prevents unexpected caving, reducing downtime and ensuring more accurate geological assessments.

Essential for managing groundwater in mining operations to ensure dry and stable working conditions. By implementing advanced pumping systems and drainage techniques, dewatering minimises water accumulation, prevents operational delays and enhances underground safety, allowing for continuous mining activities in even the most water-prone environments.

Prevents water ingress and stabilises underground tunnels. Effective dewatering reduces hydrostatic pressure, preventing potential collapses and improving structural integrity in underground spaces, ensuring long-term operational safety and efficiency in mining environments.

Reduces machinery wear by maintaining optimal working conditions. By keeping water levels under control, dewatering prevents corrosion and mechanical failures, extending the lifespan of equipment and reducing maintenance costs, leading to increased productivity and reduced downtime.

A technique that uses compressed air to clear cuttings from the borehole. This method increases drilling efficiency by preventing blockages, maintaining borehole stability and allowing for continuous operation without the need for additional flushing agents or excessive downtime.

Increases efficiency in hard rock formations. The use of compressed air enhances penetration rates, reduces bit wear and allows for deeper drilling with minimal interruptions, making it an ideal solution for high-production drilling environments.

Reduces water usage and lowers site contamination risks. By eliminating the need for excessive drilling fluids, air rotary drilling reduces groundwater contamination, decreases waste disposal costs and promotes environmentally sustainable drilling practices.

Provides critical geological and geophysical data to support mining infrastructure and project planning. By conducting thorough site assessments, it helps identify subsurface conditions, ensures structural stability and optimises excavation processes, minimising risks and maximising efficiency in mining operations.

Assesses ground stability before excavation begins by evaluating soil composition, rock strength and potential fault lines.

Identifies potential hazards to improve mine safety by assessing geological formations, monitoring ground movement and implementing proactive reinforcement measures.

An advanced core drilling method offering high precision and minimal sample contamination. By employing specialised diamond-tipped drill bits, it ensures accurate geological sampling, enhances efficiency in deep exploration and supports strategic resource planning for optimised mineral extraction and mining operations.

Delivers undisturbed core samples for in-depth analysis.

Provides valuable data for deep ore body assessments.

A crucial process for controlled rock fragmentation in mining and quarrying operations. By precisely drilling blast holes, it optimises fragmentation, ensures uniform particle size and improves downstream processing, reducing overall operational costs and increasing efficiency in mineral extraction and transportation.

Ensures uniform fragmentation for efficient material handling.

Enhances cost-effectiveness and minimises environmental impact.

A ground-breaking system that enhances tunnel development without the need for traditional drill and blast techniques. By utilising a continuous cutting process, it significantly reduces environmental impact, enhances project timelines and ensures greater structural stability in underground excavation.

Increases tunnel development speed, reducing project timelines and enabling mines to become operational more quickly.

Enhances operational safety by minimising human exposure to excavation risks, reducing the reliance on hazardous blasting methods.

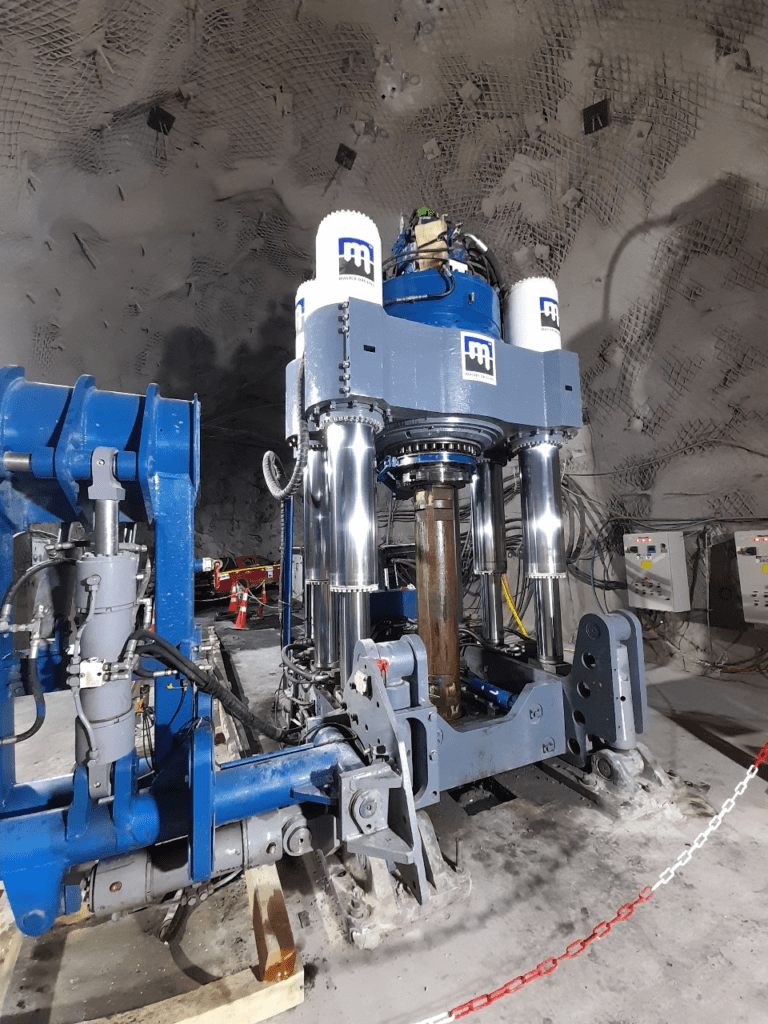

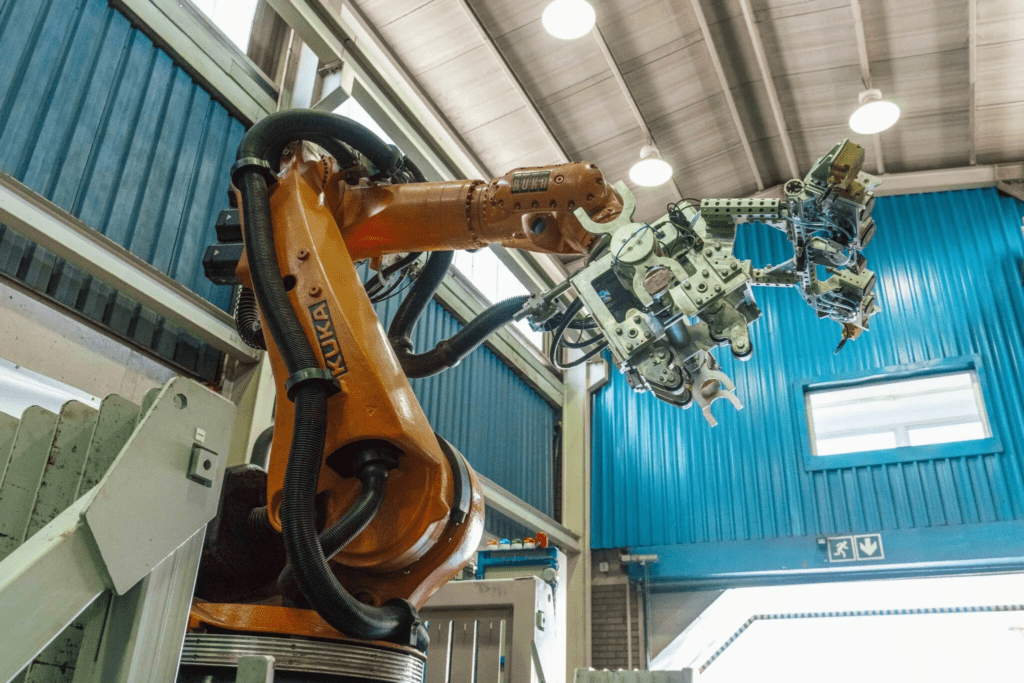

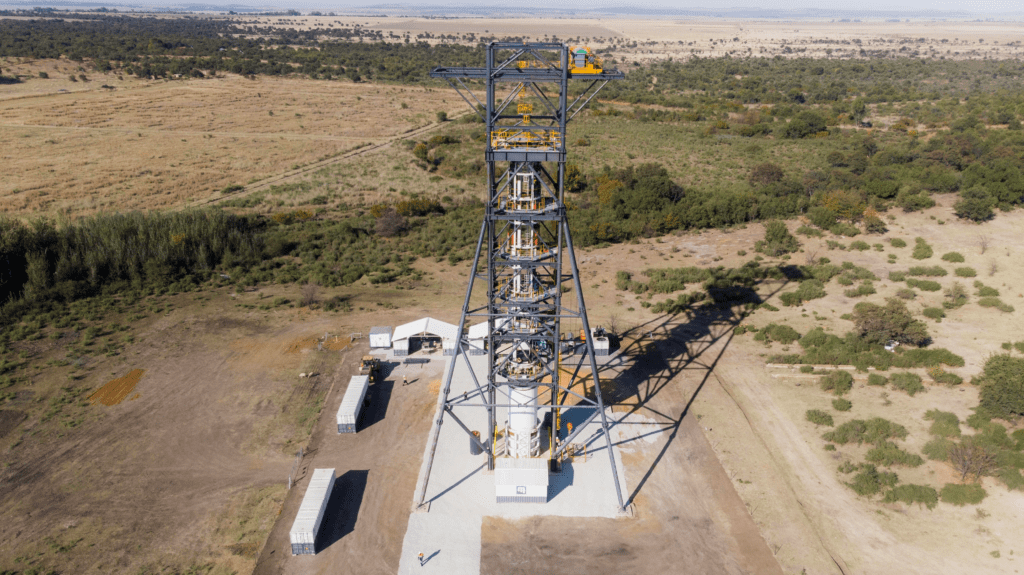

A fully mechanised method for shaft sinking, significantly reducing safety risks and increasing efficiency. By leveraging automation and precision engineering, it minimises human intervention, accelerates excavation speed and ensures consistent structural integrity, making it a game-changer for deep mining projects.

Allows for rapid vertical development without traditional excavation methods, improving project timelines and reducing workforce exposure to hazards.

Reduces operational downtime, optimising resource extraction by increasing productivity and ensuring a streamlined shaft sinking process.

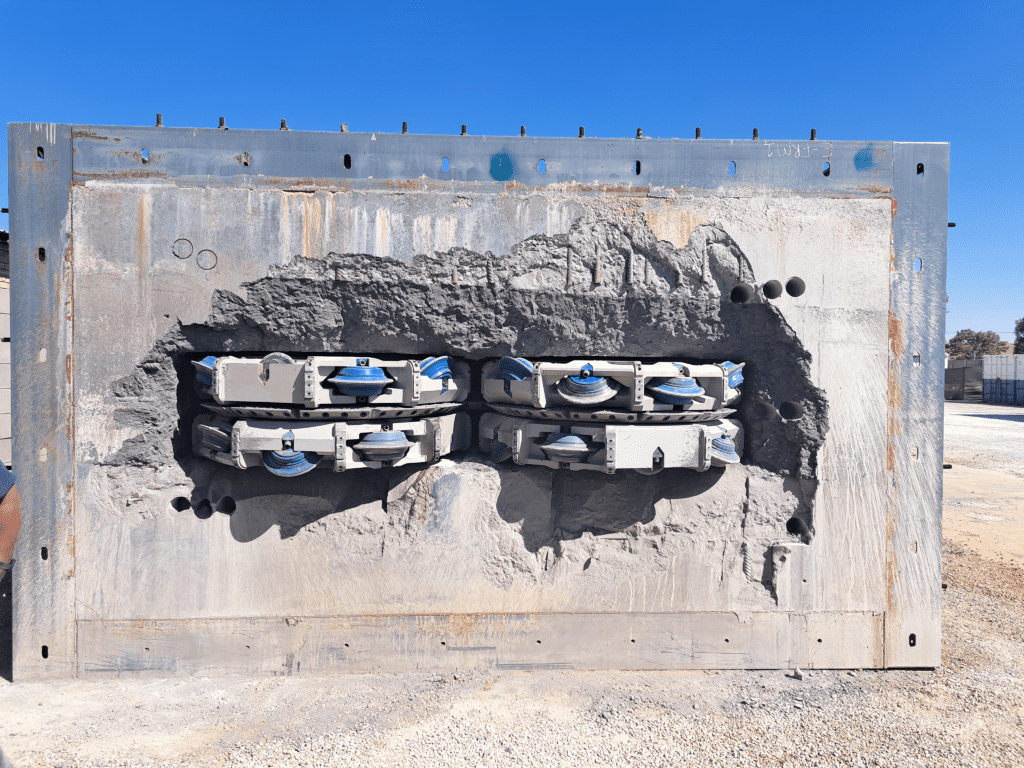

Developed in collaboration with ARM (African Rainbow Minerals), this technique allows precision ore body extraction while minimising waste. By integrating advanced automation and cutting-edge drilling techniques, it enhances selectivity, reduces environmental footprint and improves overall ore recovery efficiency, making it a sustainable and cost-effective solution for modern mining operations.

Improves ore recovery rates while reducing environmental impact by ensuring minimal dilution and selective mining practices.

Ensures cost-effective extraction of narrow reefs with minimal dilution, maximising profitability while maintaining environmentally responsible mining practices.

A&R Group delivers tailored mining solutions with a focus on underground excavation, shaft development and engineering support. By leveraging industry-leading expertise, they provide innovative and cost-effective services that improve operational efficiency, safety and sustainability in complex mining environments.

Offers tailored engineering solutions for underground mining operations, helping clients overcome unique challenges in complex mining environments.

Provides innovative support for rock excavation and shaft development, ensuring stability and safety in underground operations.

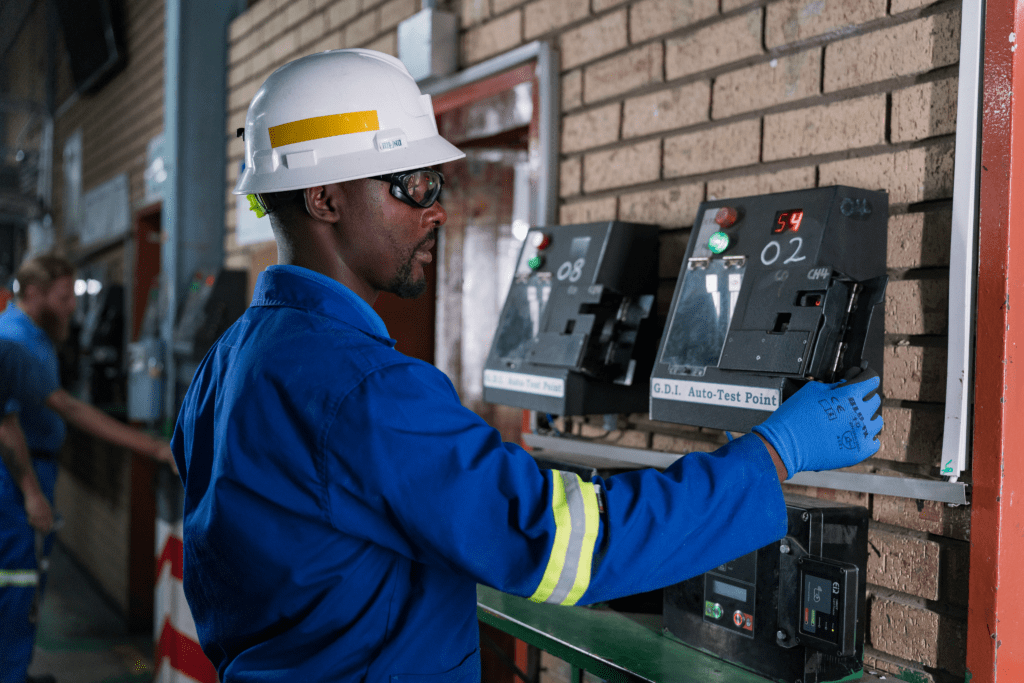

AVA delivers cutting-edge mining technology solutions, focusing on automation, digitalisation and drilling advancements. Their expertise enhances operational efficiency, reduces downtime and improves safety across various mining applications, ensuring cost-effective and sustainable resource extraction for the modern mining industry.

Focuses on advanced automation and drilling technology solutions, enhancing efficiency and operational safety across various mining applications.

Enhances mining efficiency through digital and mechanical innovation, ensuring cost-effective and sustainable mining operations.

Our experts are ready to discuss how Master Drilling North America delivers efficiency and precision to your drilling needs—reach out today.

Master Drilling North America: Regional knowledge, global strength, delivering precision drilling solutions across the globe.

Contact

USA Office

2600 South Shore Boulevard, 300 League City, Texas, USA 77573

Canada Office

2838 Belisle Drive, Val Caron, Ontario, Canada, P3N 1B2

Global HQ

4 Bosman Street, Fochville, 2515, Gauteng, South Africa